Take Full Advantage Of Efficiency With Long Lasting Undercarriage Parts

In the realm of hefty machinery and tools, the function of undercarriage parts is paramount in ensuring ideal performance and durability. The performance and performance of these elements can substantially affect the total procedure of machinery, making the choice of resilient undercarriage parts an essential decision for supervisors and operators alike. By exploring the elaborate relationship between toughness and performance in undercarriage parts, a deeper understanding of the subject arises, clarifying the pivotal aspects that drive operational success. As we navigate via the complexities of undercarriage longevity, element, and upkeep option, a comprehensive expedition awaits to introduce the crucial approaches for attaining peak performance in durable applications.

Benefits of Making Use Of Durable Undercarriage Parts

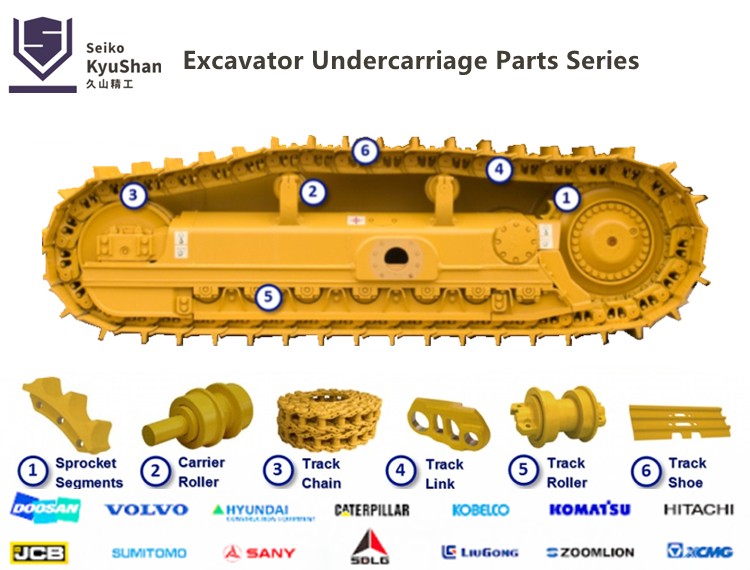

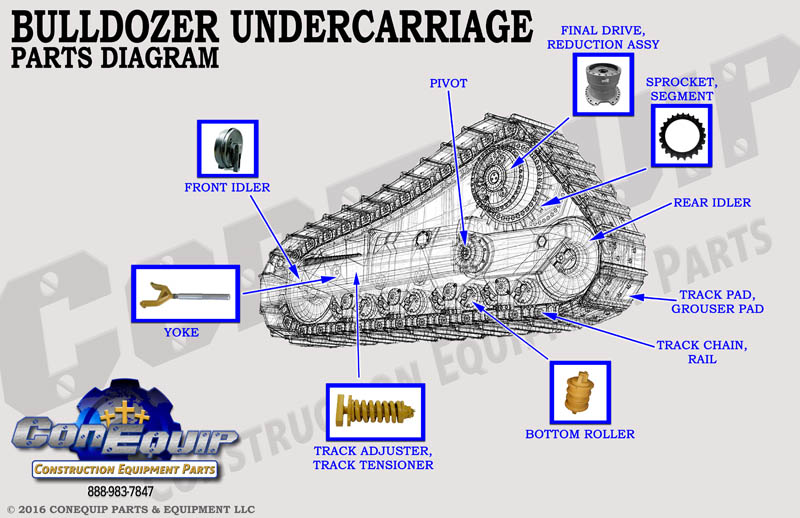

Utilizing durable undercarriage parts not just enhances the longevity of heavy machinery yet additionally decreases upkeep costs considerably. By investing in premium undercarriage elements, such as tracks, gears, idlers, and rollers, equipment operators can experience increased uptime and boosted total efficiency.

Moreover, the durability of hefty equipment is straight linked to the high quality of its undercarriage components. Sturdy elements can hold up against the roughness of requiring applications, making certain that the equipment stays functional for extended periods. Therefore, drivers can stay clear of pricey downtime and upkeep expenses, eventually maximizing the roi for their machinery.

Elements Affecting Undercarriage Longevity

The durability of undercarriage components in heavy equipment is affected by various essential elements that directly impact efficiency and durability. Top quality products, such as hardened steel, are important for holding up against the extreme conditions and heavy loads that undercarriage components are subjected to - undercarriage parts.

Additionally, ecological elements can have a significant influence on the longevity of undercarriage components. Exposure to unpleasant materials, severe temperatures, and rough working conditions can increase damage on undercarriage elements. Picking undercarriage parts that are particularly made to endure these ecological difficulties is crucial for ensuring toughness.

Furthermore, the layout and design of undercarriage parts have a direct impact on their longevity. Parts that are designed to distribute loads uniformly, minimize rubbing, and minimize tension concentrations are most likely to have a much longer life-span - undercarriage parts. By taking into consideration these essential factors, tools drivers can maximize the resilience and efficiency of their undercarriage elements

Upkeep Tips for Prolonging Undercarriage Life

Implementing normal maintenance routines is essential for prolonging the lifespan of undercarriage parts in heavy machinery. Furthermore, ensure that the undercarriage is appropriately lubed according to supplier standards to decrease rubbing and stop premature click here for more info wear.

An additional important upkeep suggestion is to maintain the undercarriage clean from dust, rocks, and particles. Buildup in the undercarriage can increase wear and corrosion, causing costly fixings. Washing the undercarriage after procedure in severe conditions is advised to stop these concerns.

Finally, monitoring and recording maintenance activities can aid in creating an aggressive maintenance routine. Maintaining detailed documents of repair work, assessments, and substitutes can supply beneficial insights into the undercarriage's condition and performance with time, assisting in forecasting and avoiding potential failures. By complying with these maintenance pointers diligently, operators can considerably boost the longevity and performance of undercarriage parts in heavy machinery.

Picking the Right Undercarriage Elements

Selecting ideal undercarriage elements is important for making the most of the efficiency and long life of heavy equipment. When it comes to selecting the right undercarriage parts, there are several variables to take into consideration.

Choosing for read reputable brands known for producing high-performance and resilient undercarriage components can dramatically influence the overall effectiveness and durability of the equipment. By carefully selecting the appropriate undercarriage components, equipment owners can enhance productivity, minimize downtime, and expand the life expectancy of their hefty equipment.

Situation Studies: Improved Efficiency With Long Lasting Parts

Including resilient undercarriage parts has actually demonstrated substantial enhancements in machinery efficiency. Discover More One study entailed a building company that updated its excavator's undercarriage components to a lot more resilient alternatives. The business observed a noteworthy decline in downtime because of undercarriage upkeep, resulting in raised productivity and price savings. The long lasting components stood up to harsh working conditions, lowering deterioration dramatically.

In an additional circumstances, a mining operation replaced the undercarriage parts of its excavator with high-quality, resilient options. This button brought about an exceptional renovation in the excavator's maneuverability and overall performance. The maker can browse tough terrains a lot more effectively, leading to improved functional efficiency and minimized gas consumption.

In addition, a logging business invested in durable undercarriage components for its forestry tools. These situation studies highlight the tangible advantages of utilizing resilient undercarriage parts in maximizing machinery performance and longevity.

Conclusion

To conclude, using resilient undercarriage components can dramatically boost performance and long life of heavy machinery. Elements such as appropriate maintenance and choosing the ideal parts play a crucial duty in making best use of undercarriage toughness. By executing these techniques, companies can reduce downtime, boost efficiency, and eventually minimize functional prices. Study have revealed that purchasing long lasting undercarriage components can result in boosted overall efficiency and performance in different sectors.

The performance and effectiveness of these elements can considerably influence the general procedure of equipment, making the option of durable undercarriage parts a vital choice for supervisors and drivers alike.Including durable undercarriage parts has demonstrated considerable improvements in equipment efficiency. These instance researches highlight the tangible benefits of making use of sturdy undercarriage parts in optimizing machinery efficiency and long life.

In conclusion, utilizing resilient undercarriage components can significantly boost efficiency and longevity of heavy machinery (undercarriage parts). Case studies have shown that spending in sturdy undercarriage components can lead to enhanced overall performance and productivity in various sectors

Comments on “Opening Longevity: The Importance of Quality Undercarriage Parts in Construction”